From the Theatre to the Hospital

UIC partners with Chicago Shakespeare Theater to put skilled artists to work making masks for patients

Artists Help Front-Line Healthcare Workers

They used to outfit performers on Chicago’s theater stages, but today costume fabricators from across the city are making patient masks for healthcare settings in the fight against COVID-19 as part of a new partnership between UIC’s College of Architecture, Design and the Arts (CADA) and the Chicago Shakespeare Theater.

New CDC recommendations that patients wear masks in healthcare settings are straining already scarce supplies. To CADA Dean Rebecca Rugg, the potential shortfall is an opportunity for skilled artists sidelined by the governor’s stay-at-home order to help front-line healthcare workers fight the deadly disease.

With $20,000 in seed funding from UIC’s leadership, Rugg enlisted CADA faculty and staff, the UIC Innovation in COVID-19 Working Group and the Chicago Shakespeare Theater to design and approve cotton face masks for patients and to pay skilled artists in the theater’s costume shop to fabricate them. The goal is to raise additional funds to deliver 250,000 masks to hospitals and convalescence wards throughout the Chicagoland area.

“The live arts got hit really hard by this pandemic right away,” said Rugg. “Places where people gather are dangerous, so productions and theaters are getting shut down and laying people off. This felt like a way to help the health system and help the suddenly unemployed fabricators in our industry.”

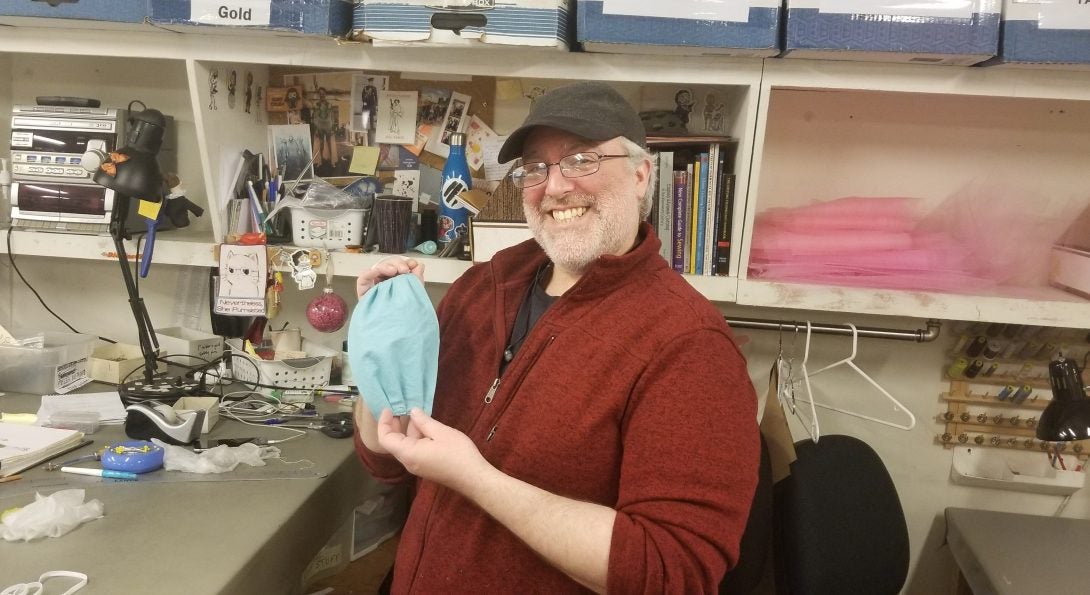

Myron Elliott, assistant professor in UIC’s School of Theatre and Music, brought his experience as a costume designer and technician to the design and sourcing of materials for this project. Elliott worked with Dr. Yannek Leiderman, a retinal surgeon who leads the Vitreoretinal Microsurgery Laboratory and part of the UIC Innovation in COVID-19 Working Group, to validate his design and materials with input from the Hospital Incident Command Group and Environmental Health and Safety Office. The UIC Innovation in COVID-19 Working Group is supported by the Dean of the College of Medicine, Dr. Mark Rosenblatt.

Rebecca Rugg

This felt like a way to help the health system and help the suddenly unemployed fabricators in our industry. –CADA Dean Rebecca Rugg

Artists make masks

Working in a health care setting was a new experience for Elliott, who spent his career in theater costume shops across the city. “I usually make clothes for imaginary people. But these masks are for real people and do an important job. It brought a sense of urgency and pride to my work in a time when I feel a little helpless,” he said.

According to Leiderman, a healthcare worker’s surgical mask must accomplish two things. It helps to stop the spread of germs from the mouth and nose of a healthcare worker to a patient during a procedure and stop the transmission of germs from patients to the healthcare worker, generally by preventing exposure to fluid, spray or splashes. It’s important to note that a surgical mask is not the same as a surgical respirator, such as an N95 respirator mask. Placing masks on patients and visitors in the hospital setting has one goal. The mask must contain germs and prevent transmission to others, called source control; resistance to splashes and liquids is not an issue. Together, the bioengineering and costume design teams settled on a 100 percent cotton, double-layer design.

“As a physician and surgeon, it’s rewarding to be part of a project that is helping our team at UI Health. As a member of the Chicago community, it’s also very gratifying to help our arts and theater community,” Leiderman said.

Marcia Lausen, director of the UIC School of Design and Philip Burton, professor and chair of Graphic Design, packaged and branded the materials for the fabricators. In the meantime, the Chicago Shakespeare Theater had its costume shop deemed “essential” by the City of Chicago and hired staff to assemble the masks. The theater will deliver the first 5,000 pieces to UI Health on Friday, April 3.

Paying the fabricators is especially gratifying to Rugg, who compares the project to President Franklin Roosevelt’s Works Progress Administration efforts during the Great Depression. Back then, the government paid people to do the work that fit their skills and help lift the country’s economy.

As most of us spend our days at home, we are turning to the arts—books, movies, music—to get us through. “When it comes to making sense of this, everyone is turning to the arts in this moment for connection. I think we are essential in that regard,” said Rugg.